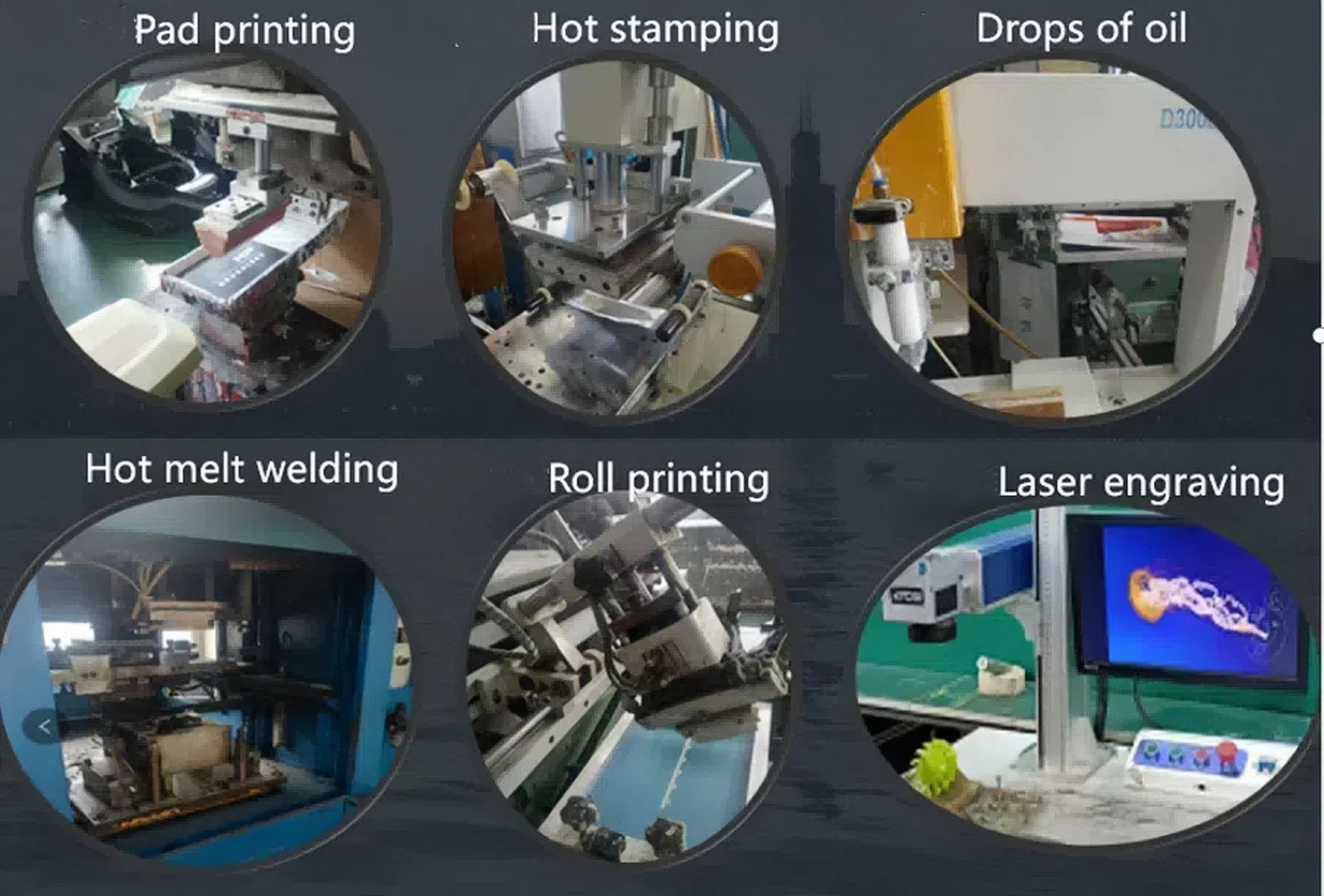

Secondary Processing

Silk screen printing, pad printing, roll printing, oil dripping, hot melt, laser engraving, etc.

The secondary processing department is the first department to be added in addition to injection molding. At present, our secondary processing department is equipped with screen printing and transfer printing production lines, ultrasonic welding machines, laser engraving machines, rolling machines, hot melt welding machines and other equipment, which can be used for transfer printing, screen printing, oil injection, ultrasonic, laser engraving and other post-processing services to meet the different requirements of customers on products.

Pad Printing

Pad printing is a process applying ink to a plastic part's surface using a silicone pad. It is commonly used to apply images, logos, or text on irregularly shaped or curved surfaces. This technique is widely used in industries like electronics, toys, and automotive parts for adding decorative or informative details.

Hot Stamping

Hot stamping is a process applying colored or metallic foil to the surface of a plastic parts using a heated die. The heat and pressure cause the foil to bond to the plastic, creating a permanent design. Hot stamping gives products a premium, long-lasting surface and is frequently used to add metallic finishes, logos, or lettering.

Drops of Oil

"Drops of oil" is a technique applied to plastic surfaces to produce a particular tactile or visual impact. In this process, small amounts of oil or lubricant are given to the surface of the plastic part, which can give it a glossy, shiny, or smooth finish. This method is typically used to enhance the appearance or feel of the final product.

Hot Melt Welding

Hot melt welding, also known as hot plate welding, is a technique used to join two plastic parts together by melting their surfaces using a heated tool. Once the surfaces are melted, they are pressed together to form a strong, permanent bond. This method is often used in applications where airtight or watertight seals are required, such as in automotive or medical devices.

Roll Printing

Roll printing, sometimes referred to as roller coating, is a process where a patterned roller is used to apply ink or coating to the surface of a plastic parts. Patterns, textures, and coatings that are continuous or cover a vast area are perfect applications for this approach. It is commonly used for decorative finishes on plastic sheets, panels, or components.

Laser Engraving

Laser engraving is a process that uses a laser beam to etch or mark the surface of a plastic parts. The laser removes material to create precise, permanent designs, such as logos, serial numbers, or text. This method works well with a variety of plastic kinds and can be applied to complex or complicated designs.

These post-processing techniques allow manufacturers to enhance the visual appeal, functionality, or brand identity of plastic products, making them more attractive and effective in their intended applications.